How to Choose the Best Countertop for Your Cooking Habits

Choosing the right kitchen countertop isn’t just about aesthetics—it’s about how well the surface supports your daily cooking routine. Whether you’re a passionate home chef,

Use this guide as a reference outline to help make your project go smoothly.

Your project is important to us and we are excited to help you through the process of decisions, products and understanding fabrication of your new material.

Use this guide as a reference outline to help your project go smoothly.

Your project is important to us and we are excited to help you through the process. Valley View Granite is an accredited affiliate of the National Stone Institute and follows the standards set forth by the NSI.

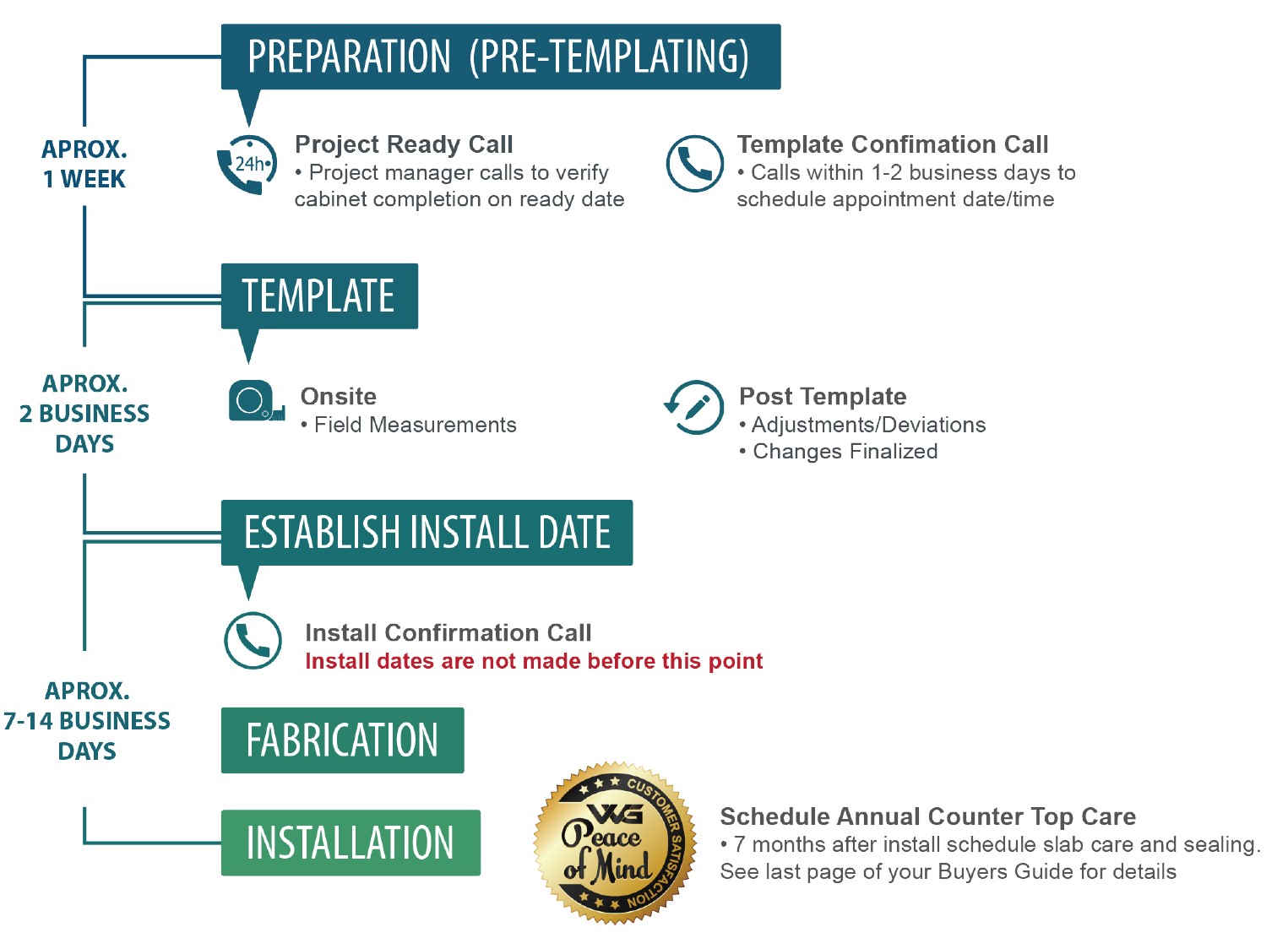

The following represents approximate timeframe only.

This does NOT constitute a contract or commitment. Project size, custom features, and material availability are additional variables that can also affect turn around times.

Below are a summary of action items needed for your project. See noted steps for additional information.

Some of the things that you will be asked during a consultation are:

To receive the most accurate estimate for your project we will need:

You will be provided with an estimate and layout, please review this for accuracy.

This is an estimate only and may change based on final measurements, material selection and edge choice.

VVG requires a minimum of 16 sq. ft. to template, fabricate & install a project. Fabrication only (customer supplied drawings) has no minimum sq. ft. requirement.

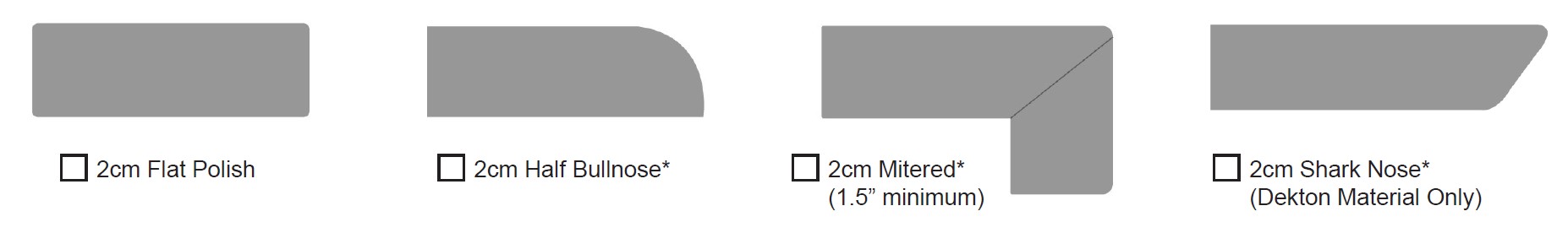

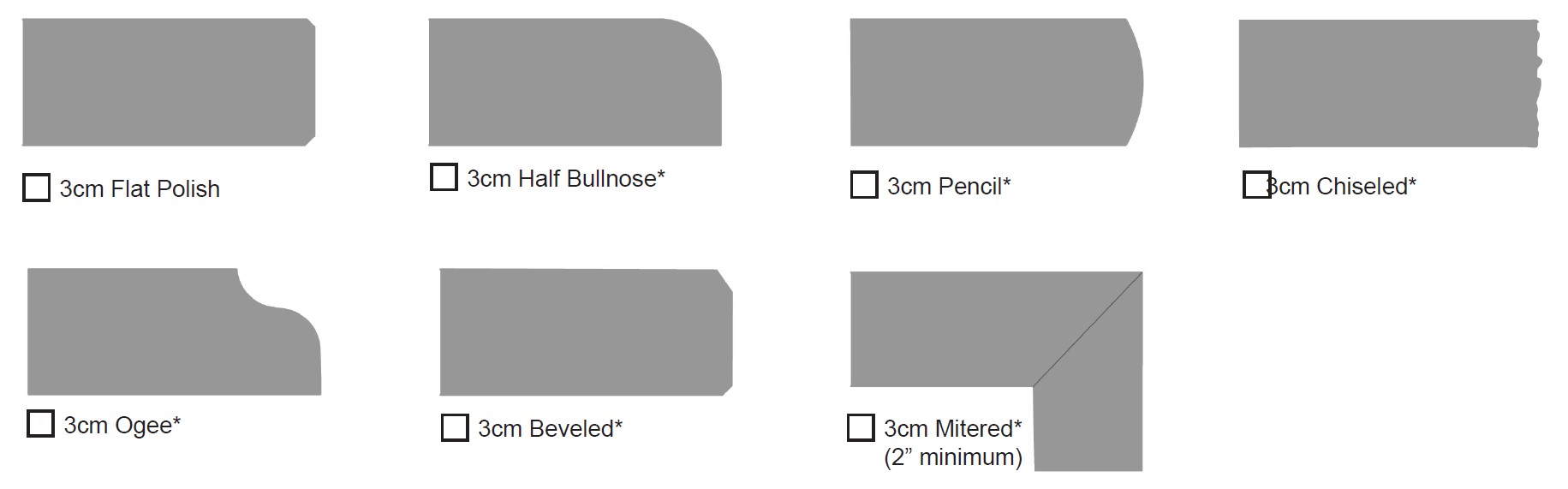

Granite, marble, and quartz typically come in two thicknesses: 2cm (3/4”) or 3cm (1 3/16”). 3cm thickness is usually the most popular and cost effective. VVG stocks this size as it is generally not necessary to “build up” the edge profile. Some materials, typically used in shower surrounds, fireplace surrounds, or decorative will be 1cm-1.6cm thick. Below are visual examples how edges are created.

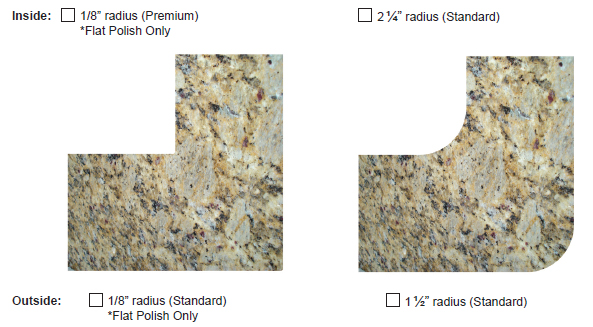

Would you like your outside corners square or round?

You can view examples of different corner types during your showroom consultation or shown below. Typically, square is a more modern look and round is a “softer” look.

You can view examples of different corner types during your showroom consultation or shown below. Typically, square is a more modern look and round is a “softer” look.

Select your corner radius.

To prevent tipping, overhangs cannot be longer than 1/3 of the width of the countertop.

VVG Sales Consultants are not trained to determine the suitability of specific fixtures or appliances. However, we will work with you and your supplier to help evaluate whether the components’ sizes and characteristics fit your project.

Ask about appliance compatibility prior to purchasing new appliances.

Supply VVG the make, model numbers, and spec sheet of appliances that need to be cut into the counter.

Drop-in cooktops will need to be on-site at time of template. They will be “dry fit” at time of installation. Failure to have this on-site will result in an additional “trip charge”.

Freestanding ranges (most common), which have the controls on the back, will generally require a 30” opening and the sides will be polished. These ranges are not required to be on-site.

Slide-In range or cooktop with the controls on the front must be on-site at time of install. These usually require a “filler” piece of counter behind the range and may require the front of the counter to be “notched.”

Most dishwashers will attach to the cabinets on the side of the flange, however VVG will add a metal dishwasher bracket to all jobs that spans a dishwasher opening (24").

Shown below are the most common cooking range applications.

VVG stocks a variety of high quality undermount sinks.

If you are providing the sinks, they need to be ON SITE at time of template and placed in the correct location. All farm style sinks need to be sitting in cabinet box with the top of sink flush with the top of cabinets at time of template. Custom sinks may require an additional drafting fee.

VVG stocks a variety of high quality undermount sinks.

Provide sink models and who is providing the sink(s).

Specify your choice of sink material.

It is recommended to wait 24 hours after install to connect plumbing.

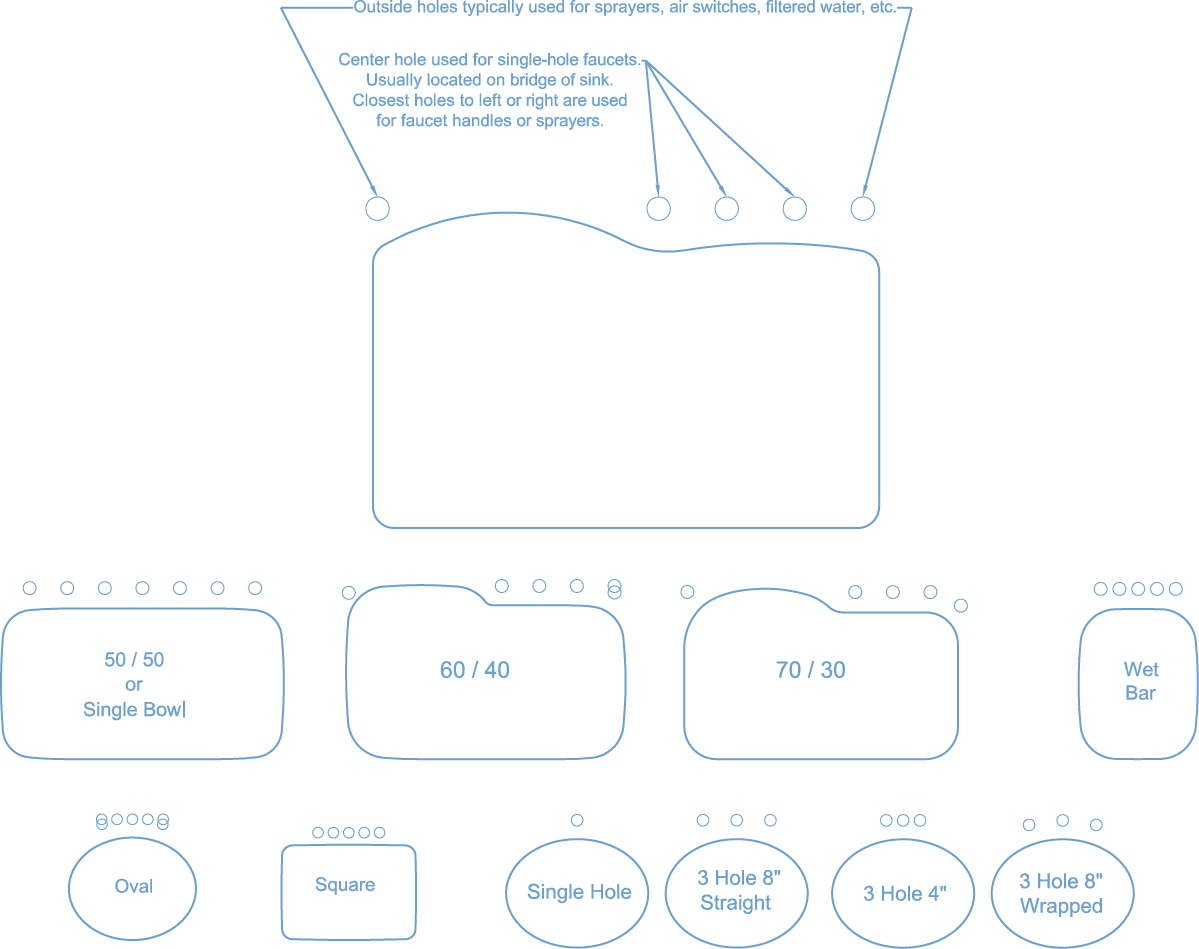

Prior to template, provide the faucet model number and number of faucet holes required and the placement in relation to the sinks you choose.

The standard size of a faucet hole is 1 3/8”. A single hole faucet is generally easier to clean around. Will an “air switch” be required for a garbage disposal in an island? Will a sprayer be installed?

Provide sink models and who is providing the sink(s).

Please inform your sales rep if you have any special color requirements for your caulking.

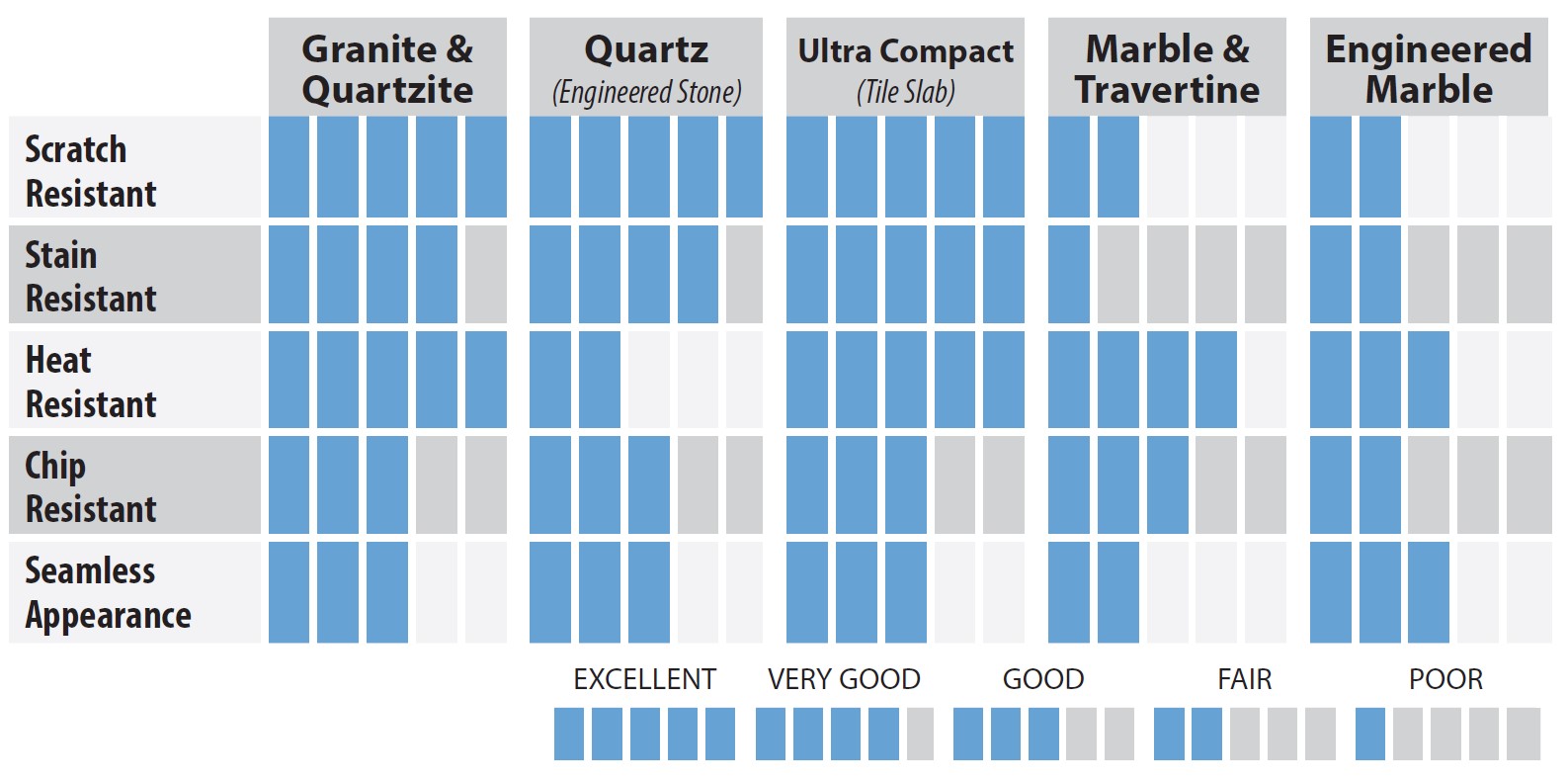

Material selection is probably the hardest and one of the most important parts of the countertop buying process. VVG carries a large inventory which is competitively priced. You are also welcome to select materials from your choice of vendors. Ask a consultant for a list of local material suppliers.

Color variation is expected and an exact match to samples cannot be guaranteed.

Slab materials are priced in two ways:

Which model is more cost effective is entirely dependent on your budget.

VVG does not guarantee vein flow match. VVG staff will do their best to have veins line up but this is not a cause for remake. Perfect Vein matching is not guaranteed even when a layout is approved.

One of the advantages that VVG offers, when you buy by the slab, is the ability to view your layout prior to purchasing.

Prior to templating:

A Return Trip Charge will be assessed for items not on-site at time of template.

Holes drilled at time of installation will incur an extra charge.

Prior to template (for remodel)

If client chooses to not continue with the job and the material is cut, the deposit will not be refunded. If the job has not been cut, $300 plus any restocking or return fees will not be refunded.

Once you have everything completed for your order, your project will be submitted to a Project Manager who will review everything and contact you confirming the earliest date your project will be ready for templating.

Your Project Manager will be working closely with you to ensure that everything runs smoothly through the entire field measure, fabrication and installation processes. They will help you with the scheduling, post field measure and installation events.

For any scheduling questions please contact the project management team at (435) 257-7814

Your templating specialist will be measuring and electronically creating / submitting the final CAD drawings for production.

In order to provide the best possible processing time, our goal is to be fabricating your job within 4-8 hours after he has field measured. This is why it is imperative that ALL decisions be made and information provided prior to your templater arriving at the jobsite.

Template appointments usually last between 30 minutes and an hour depending on the size of job. The following activities will be done while they are on site

Please have someone familiar with the job requirements available either in person or via phone for questions during the appointment.

Incomplete items at time of template could delay your installation date assignment.

– A new sale order approval may be required

– A new layout may be required if you are purchasing material “by the slab”

In the event that material is not in stock, the completion date will not be assigned until the material arrives at VVG fabrication facility and any necessary layout approvals are received.

No changes can be made after a job has been approved for production.

The following represents approximate delivery times only. It does NOT constitute a contract or commitment. Project size, custom features, and material availability are additional variables that can also affect turn around times.

Children or animals underfoot puts them at risk! We ask on the day of the installation your animals be kenneled and, if possible, arrange for your children to be with a caregiver.

We recommend waiting 48 hours before preparing food on your countertops to ensure that sealant is fully absorbed and cured.

Care will be exercised during the installation process; however, during tear out of existing counters, and installation of new tops, some unavoidable damage may be done to existing tile, backsplashes, drywall, wallpaper, and paint. These items are considered incidental damage and are the customer’s responsibility to repair.

VVG Field Service hours are between 8:00 AM and 4:00 PM Monday – Friday.

Any field services required after 4:00 PM will be billed for overtime.

Scheduling communications and supervisor permission for overtime must be approved prior to scheduling.

Work performed after 4:00 PM because of VVG workload will not be billed overtime.

Final payment is expected day of completion or according to the terms with the account. If remaining balance is not paid within 30 days of install completion, customer agrees to pay 18% per annum on any unpaid balance, compounded monthly beginning 30 days after the invoice date. All discounts will be forfeited if account exceeds 30 days. Payment can be given to the installers, dropped off at a VVG location, mailed into a VVG location, or a CC payment can be made over the phone by calling VVG, 435-257-7882 and asking for the Accounts Receivable Department.

Scheduling communications and supervisor permission for overtime must be approved prior to scheduling.

Regardless of material, VVG always recommends that your slab is professionally maintained annually, giving you the peace of mind that your slab will continue to exceed performance expectations.

Choosing the right kitchen countertop isn’t just about aesthetics—it’s about how well the surface supports your daily cooking routine. Whether you’re a passionate home chef,

With the NBA playoffs starting next month, we at Valley View Granite thought it would be a good time to revisit the work we did at Vivint Smart Home Arena, the home of the Utah Jazz.

Stress-free countertops. on-time, in budget!

Enter your information, and our team will reach out shortly!